LED COB LED: The Definitive Guide to COB vs SMD and LED Technology

Have you ever shopped for LED strips, downlights, or studio lighting and wondered: “Is COB better than SMD?” or “Which is more efficient, led vs cob led?” These debates swirl across forums, data sheets, and design specs. But not every source gives you the full picture — some simplify, some exaggerate.

That’s why this article is structured to help you really understand led cob led technology: what it means, when it shines, and when another LED type may serve you better. As you browse through, you’ll see comparisons, examples, and best practices — all backed by credible sources — so you can make confident decisions. Let’s start with the fundamentals.

Fundamentals: What Is LED Technology?

When we talk about modern lighting, LED technology sits at the heart of the conversation. Whether you’re comparing LED vs COB LED, exploring the benefits of SMD or LED, or simply trying to understand the COB LED definition, it’s important to start with the basics. So, what exactly is an LED, how does it work, and why has it transformed the lighting industry?

The Science Behind LED Lighting

LED stands for Light Emitting Diode, a semiconductor device that produces light through a process called electroluminescence. When an electric current passes through a semiconductor material, electrons recombine with holes inside the device, releasing energy in the form of photons — visible light. This mechanism is fundamentally different from traditional incandescent bulbs, which rely on heating a filament until it glows, or fluorescent lamps, which use gas discharge and phosphors.

The efficiency of this process is one of the main reasons LED technology is considered revolutionary. A typical LED can convert over 80% of electrical energy into light, compared to only about 10% for incandescent bulbs. That means more brightness, less wasted heat, and lower energy bills — all in a much more compact form factor.

Evolution of LED Packaging and Mounting

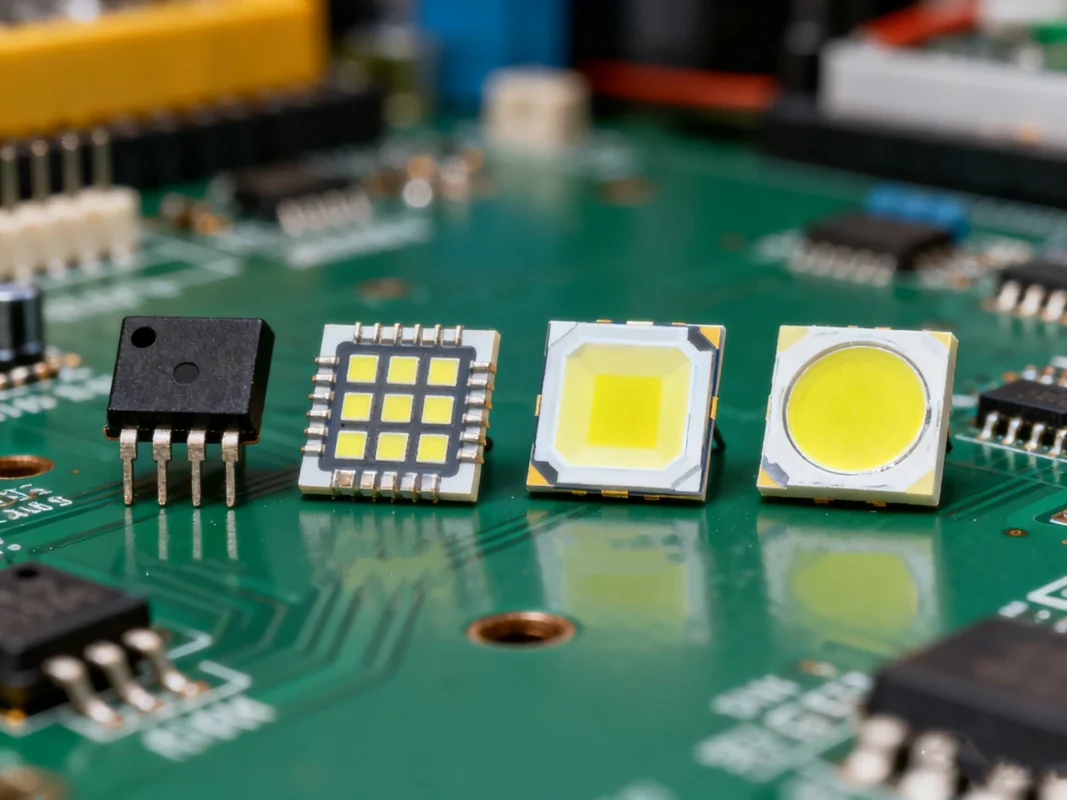

The term LED itself is quite broad, encompassing various designs and configurations. Over time, manufacturers have developed different ways to package and mount LED chips to improve their performance, versatility, and cost-effectiveness. The most widely used types today include:

- DIP (Dual In-line Package): The earliest form of LED, with two leads inserted into a circuit board. Though reliable, DIP LEDs are bulky and less efficient by today’s standards.

- SMD (Surface-Mounted Device): A major leap forward, SMD LEDs are soldered directly onto the surface of a PCB. They are smaller, brighter, and more versatile, often used in LED strips, displays, and general lighting.

- COB (Chip on Board): A newer innovation, COB LED technology mounts multiple LED chips directly onto a single substrate, creating a dense, powerful light source with superior uniformity.

- DOB (Driver on Board): An emerging design that integrates the driver circuit directly onto the board, reducing external components and simplifying design.

Each of these mounting types represents a step forward in how LED technology is applied. The evolution from DIP to SMD or LED and finally to COB LED shows how far the industry has come in improving efficiency, brightness, and light quality.

Why Packaging Matters in LED Performance

Packaging isn’t just about physical structure — it plays a crucial role in how an LED performs. It affects everything from thermal management and light distribution to cost and durability. For example, COB LEDs excel at providing high lumen output and smooth, uniform light from a compact source. SMD LEDs, on the other hand, offer greater flexibility and are easier to integrate into different designs, especially where multiple colors or directional control are needed.

When choosing between LED COB vs SMD, understanding these foundational differences is key. Packaging influences not only how much light is produced but also how that light is distributed and how efficiently the system manages heat — all critical factors in long-term performance.

COB LED: Definition, Structure & Working Principle

Before we dive into the comparisons of LED vs COB LED or LED COB vs SMD, it’s crucial to understand what a COB LED actually is, how it’s built, and why it’s become a go-to choice in modern lighting. Grasping the COB LED definition and its working principle will help you make smarter decisions when choosing between SMD or LED options for different applications.

What Is a COB LED? (COB LED Definition)

COB stands for Chip on Board, and as the name suggests, this technology involves mounting multiple LED chips directly onto a single substrate to form a compact, high-intensity lighting module. Instead of packaging each LED chip individually (as is done with SMD LEDs), COB technology bonds numerous bare chips side by side on the same circuit board. These chips are then encapsulated with a layer of phosphor and protective resin, creating a single, powerful light-emitting surface.

So, what’s a COB LED in practical terms? Think of it as many tiny LED chips working together as one cohesive light source. Because they’re so densely packed, the light they emit appears smooth and uniform, with no visible dots or shadows. This makes COB technology particularly useful for applications that require continuous, glare-free illumination, such as spotlights, downlights, high-bay fixtures, and architectural lighting.

In essence, the COB LED definition is all about integration and efficiency: multiple diodes combined into a single lighting module to deliver superior brightness and performance from a compact footprint.

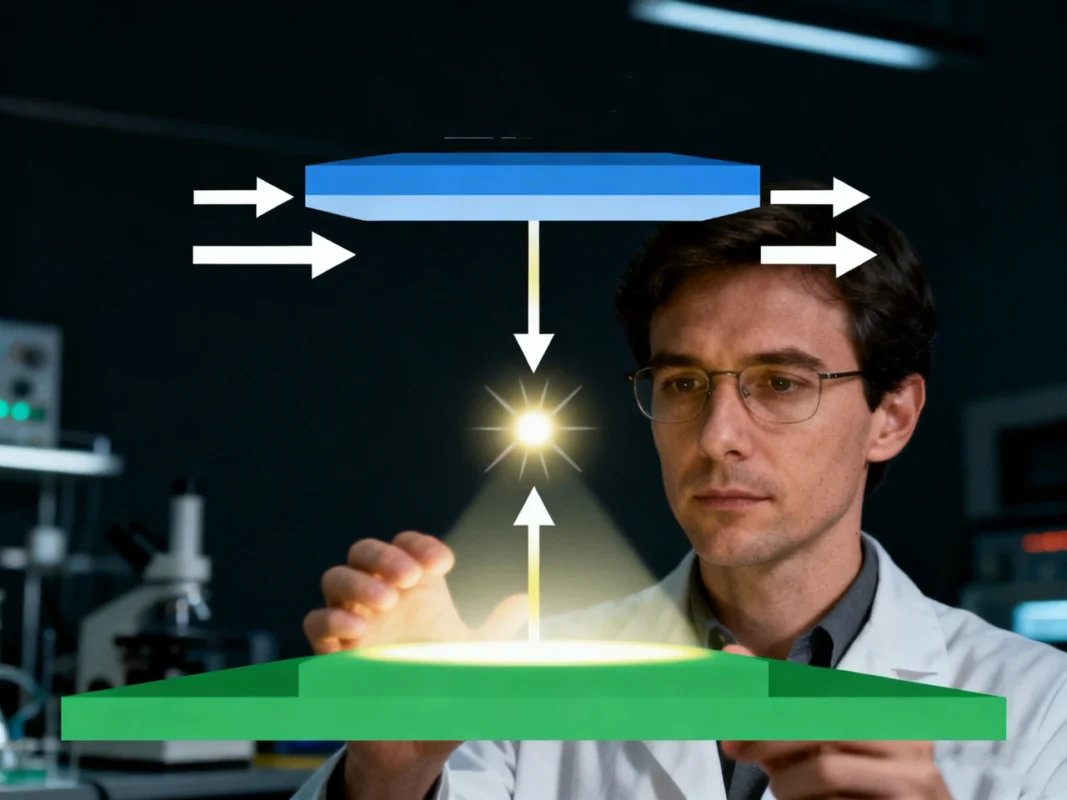

The Structure of a COB LED

The structure of a COB LED is what sets it apart from traditional LED types. Here’s a breakdown of its main components:

- Substrate/Base – Usually made from aluminum or ceramic, this base layer provides structural support and excellent heat dissipation, which is essential because COB LEDs generate significant heat due to their high power density.

- Multiple LED Chips – Instead of one large LED or several individually packaged diodes, dozens or even hundreds of tiny LED chips are bonded directly onto the substrate.

- Bonding Wires or Flip-Chip Design – These connect the chips to the circuit, allowing electrical current to flow efficiently. Advanced COB modules may use flip-chip designs to further reduce thermal resistance.

- Phosphor Coating – A thin layer of phosphor converts the natural blue light of the LED chips into white light, or other colors depending on the intended application.

- Encapsulation Layer – A protective silicone resin or epoxy layer seals the LED array, protecting it from dust, moisture, and mechanical damage.

Because the chips sit directly on the board without individual packaging, COB LEDs have a higher packing density and larger light-emitting area. This design leads to one of their biggest advantages: continuous, uniform illumination without the “dot” effect often seen in SMD or LED strips.

How COB LEDs Work

The working principle of a COB LED follows the same basic science as any other LED — electroluminescence. When a current passes through the semiconductor junction inside each diode, electrons and holes recombine and release energy as photons. What makes COB technology unique is how this process is scaled up.

Because multiple chips are arranged tightly together, their combined light blends seamlessly into a single, high-intensity output. This collective performance allows COB LEDs to achieve higher lumen density and better optical performance than many traditional LED types. The large light-emitting surface also improves beam quality, producing a smooth and consistent light field ideal for both focused and general illumination.

However, this dense chip arrangement means COB modules must manage heat carefully. Without effective thermal control, performance and lifespan can degrade over time. That’s why substrates with excellent thermal conductivity and robust heat-sinking designs are essential to any high-quality COB LED system.

Why COB LEDs Are Changing the Lighting Game

The strength of COB LED technology lies in its ability to deliver intense, uniform light from a compact source. Compared to traditional LED assemblies, COB modules reduce circuit complexity (often requiring just one driver), minimize optical losses, and offer superior light quality. These benefits make COB ideal for high-performance fixtures where consistency, brightness, and energy efficiency are critical.

Still, like all technologies, COB has trade-offs. Its concentrated heat output demands careful thermal management, and its fixed shape offers less design flexibility than SMD LEDs. Yet, in scenarios where light quality and power density matter more than modularity — from industrial lighting to architectural accents — COB LED often emerges as the superior choice.

SMD LED & Other LED Types

Now that we understand the COB LED definition and how this technology works, it’s time to look at another major category in modern lighting — SMD LED — as well as a few other LED types that play important roles in different applications. Exploring the broader landscape of SMD or LED options will help you make better decisions when comparing LED COB vs SMD solutions or evaluating which type of LED best suits your project.

What Is an SMD LED?

SMD stands for Surface-Mounted Device, a packaging method where the LED chip is mounted directly onto the surface of a printed circuit board (PCB) rather than being inserted through holes, as in older technologies. This surface-mount approach allows for much smaller, flatter, and more versatile LED modules compared to traditional through-hole LEDs.

In an SMD LED, each diode is individually packaged with its own phosphor and lens, and the assembly is soldered directly onto the PCB. This compact, lightweight design supports high-density layouts, making SMD LEDs ideal for applications like LED strips, flat panel lighting, signage, and decorative lighting. Because of their modular nature, SMD LEDs can be arranged in countless configurations and used in a wide variety of settings.

What sets SMD apart in the SMD or LED debate is its flexibility. While COB LEDs prioritize light uniformity and intensity, SMD LEDs offer adaptability — you can combine different chips to produce RGB color mixing, dynamic lighting effects, or customized beam patterns.

Advantages and Characteristics of SMD LEDs

SMD LEDs have become one of the most widely used types of LED technology, and for good reason. Here are some of their key strengths:

- Compact and Lightweight: Their surface-mounted design makes them small and easy to integrate into various lighting systems.

- Flexible Applications: Perfect for linear lighting, signage, display panels, and decorative fixtures.

- Color Mixing Capability: Multiple diodes (e.g., red, green, and blue) can be combined in a single package to produce millions of colors.

- Ease of Replacement: Because SMD LEDs are discrete components, individual units can be replaced without changing the entire fixture.

- Wide Beam Angles: Their design allows for broader light distribution compared to some COB modules.

However, SMD LEDs also come with a few trade-offs. Their light can appear as multiple points rather than a single uniform source, which might be undesirable in some applications. They may also require more complex circuit designs, particularly when multiple colors or channels are involved. These considerations often come up in the LED vs COB LED discussion when choosing the right technology for a given project.

Other Types of LEDs You Should Know

While SMD LED and COB LED dominate the current market, they’re part of a larger family of LED technologies. Each type offers unique benefits and is suited to specific use cases. Understanding them helps build a complete picture when comparing LED COB vs SMD and other options.

- DIP (Dual In-line Package) LED

DIP LEDs are the original LED form factor, featuring two lead wires that pass through holes in the circuit board. While they’re durable and simple, DIP LEDs are less efficient and less compact than modern alternatives. Today, they’re mostly used in signage, indicator lights, or outdoor displays where ruggedness is more important than compact design.

- COB (Chip on Board) LED

We’ve already explored COB LED definition and structure in depth. It’s worth reiterating that COB LEDs excel when high light density and smooth, uniform illumination are required. They are ideal for applications like downlights, high-bay fixtures, and architectural lighting where light quality matters most.

- DOB (Driver on Board) LED

DOB, or Driver on Board, is an emerging innovation that integrates the driver circuitry directly onto the LED substrate. By eliminating the need for a separate external driver, DOB LEDs simplify fixture design and reduce overall system size. However, they can be more challenging to repair or replace and may have thermal limitations depending on the design.

- MCOB and GOB LEDs

- MCOB (Multi Chip on Board) builds on COB technology by integrating multiple COB modules into a single unit, pushing efficiency and brightness even further.

- GOB (Glue on Board) is often used in display technology, where a protective layer over the LEDs increases durability and environmental resistance.

Each of these technologies represents a different trade-off between cost, complexity, brightness, heat management, and flexibility. Whether you’re comparing SMD or LED, exploring LED COB vs SMD, or simply trying to understand where COB LED fits into the landscape, knowing these alternatives gives you a more complete perspective.

Choosing the Right LED Type

The decision between LED vs COB LED, SMD LED, and other types isn’t just about which is “better” — it’s about which is better for your application. If you need flexible, modular lighting with color control and easy customization, SMD LEDs are likely the right choice. If you prioritize uniform, high-density light in a compact footprint, COB LEDs are often superior. For basic, rugged use cases, DIP LEDs still have a place, and for cutting-edge designs, DOB and MCOB technologies are worth watching.

Comparing COB vs SMD vs “Standard” LED

Once you understand the fundamentals of LED technology and the COB LED definition, the natural next step is to compare the major types side by side. The debate over LED vs COB LED, LED COB vs SMD, and even traditional LEDs isn’t about one being universally better than another — it’s about understanding how each performs in different scenarios. By exploring their strengths, weaknesses, and ideal use cases, you’ll be equipped to make an informed choice for your lighting needs.

Light Output and Uniformity

One of the most obvious differences between COB LED and SMD LED is how they emit light. Because COB technology mounts dozens of tiny chips close together on a single substrate, the light blends seamlessly into one continuous beam. The result is smooth, even illumination with no visible “dots” or gaps. This uniformity makes COB LEDs ideal for applications like downlights, spotlights, and high-bay lighting where a clean beam pattern is essential.

SMD LEDs, by contrast, are individual packages mounted separately on a board. While they can be placed close together, there’s usually visible spacing between them, which can cause a “dotted” or “pixelated” light effect if not diffused. That said, SMD designs offer a wider beam angle and more flexibility for directional lighting.

“Standard” LEDs — often referring to older DIP types — produce light from a single, larger diode. While reliable, they typically deliver less brightness per unit area and lack the refined light quality of COB or SMD solutions.

Brightness and Lumen Density

When it comes to sheer brightness, COB LEDs often take the lead. Because they cluster many chips tightly together, they can achieve higher lumen density — more light output from a smaller area. This makes them especially suitable for high-intensity lighting where powerful illumination is required from a compact fixture.

SMD LEDs, while still bright, distribute their chips across a larger area, resulting in slightly lower lumen density. However, they compensate with design versatility. For example, multiple SMD modules can be combined to achieve broader coverage or integrated color mixing — something COB modules can’t do as easily.

Older standard LEDs lag behind both technologies in this category. Their simpler design limits both lumen output and efficiency, which is why they’re now mostly reserved for basic indicator lights and signage rather than primary illumination.

Thermal Management and Heat Dissipation

Thermal performance is another major factor in the LED COB vs SMD comparison. Because COB LEDs pack many chips into a small area, they generate a lot of heat in a concentrated spot. Without proper heat sinking and thermal design, this can shorten lifespan or degrade performance over time. For high-power applications, COB fixtures often require robust heat dissipation systems to operate reliably.

SMD LEDs, on the other hand, spread their chips across a larger surface area, which naturally improves heat distribution. This means SMD modules often run cooler and may have a slight edge in longevity if thermal management is not optimized.

Standard DIP LEDs tend to run relatively cool due to their low power and simple design, but they also produce far less light — so their thermal advantage is less relevant for demanding lighting applications.

Cost, Manufacturing, and Complexity

When considering LED vs COB LED, cost and manufacturing complexity are key factors. SMD LEDs are widely produced and relatively inexpensive due to their mature manufacturing processes. They’re also easier to repair or replace individually, which can reduce maintenance costs over time.

COB LEDs, while not prohibitively expensive, generally cost more to produce because of their more complex assembly and higher material requirements. Additionally, since multiple chips are integrated into a single module, replacing one failed chip usually means replacing the entire COB unit.

Standard LEDs are the simplest and cheapest of all, but their limited performance means they’re rarely used for modern general lighting applications.

Reliability, Lifespan, and Failure Modes

All LED types boast impressive lifespans compared to older lighting technologies, but their reliability characteristics differ. COB LEDs can deliver exceptional longevity when properly cooled, but their high chip density means any thermal management issues can impact the entire module.

SMD LEDs are generally robust and easier to maintain. If one diode fails, the others continue to operate, and individual replacements are possible. This modularity gives SMD lighting a slight reliability edge in some cases.

Standard LEDs also last long but are less efficient and versatile, so they’re typically used only in niche or legacy systems today.

Color and Design Flexibility

If your lighting project demands color control, dynamic effects, or unique configurations, SMD LEDs are the clear winner. They can integrate multiple diodes (red, green, blue) into one package for RGB color mixing, enabling millions of possible hues. Their modular nature also makes them highly customizable for various shapes and sizes.

COB LEDs, by contrast, are less flexible in terms of color and configuration. Because all chips in a COB module are encapsulated together, mixing colors or creating complex patterns is more challenging. However, they excel at producing uniform white light with excellent color rendering.

Standard LEDs offer minimal flexibility and are generally fixed to a single color and form factor.

Overall Performance Comparison

To summarize the LED COB vs SMD and “standard” LED debate:

| Feature | COB LED | SMD LED | Standard LED |

|---|---|---|---|

| Light Uniformity | Excellent (smooth, no hotspots) | Good (may show individual points) | Basic |

| Lumen Density | High | Moderate | Low |

| Thermal Management | Requires robust heat sinking | Easier heat distribution | Low heat output |

| Cost & Complexity | Moderate to High | Low to Moderate | Low |

| Color Flexibility | Limited | Excellent | Limited |

| Maintenance | Entire module replacement | Individual diode replacement possible | Basic |

| Applications | High-bay, downlights, spotlights | Strips, panels, RGB lighting | Indicators, signage |

Making the Right Choice

The decision between SMD or LED, LED vs COB LED, or even standard options ultimately depends on your project’s needs:

- Choose COB LED when you need high-intensity, uniform light in a compact space — ideal for architectural, industrial, and commercial lighting.

- Go with SMD LED if flexibility, color control, and broad distribution are priorities, such as in LED strips, displays, and decorative applications.

- Reserve standard LEDs for simple, low-power uses like indicator lights and signal displays.

Performance Metrics: Brightness, Efficiency, Thermal, Reliability

When evaluating LED COB LED versus SMD or LED and other traditional types, understanding the key performance metrics is essential. Metrics such as brightness, energy efficiency, thermal management, and reliability determine how well a lighting solution performs in real-world applications. Let’s break down these critical factors to help you make an informed decision.

Brightness – How Much Light Do LEDs Produce?

Brightness, measured in lumens, is one of the first things to consider in the LED vs COB LED debate. COB LEDs are engineered to pack multiple chips onto a single substrate, creating a highly concentrated light source. This results in a high lumen density, meaning more light output per unit area. It’s why COB LEDs are often used in spotlights, high-bay lighting, and downlights where intense illumination is required.

SMD LEDs, on the other hand, distribute individual diodes across a surface. While they can cover a larger area, their lumen density is typically lower than COB LEDs. However, their design flexibility allows for evenly spread lighting over broader surfaces, which is ideal for panels, strips, or decorative installations.

Older standard LEDs generate significantly lower brightness due to fewer diodes and less efficient packaging. They are generally suitable for indicator lights or low-intensity applications rather than general illumination.

Energy Efficiency – Maximizing Light Per Watt

Energy efficiency is a critical metric for both cost savings and sustainability. COB LEDs are highly efficient because multiple chips working together reduce the need for additional circuitry and optical elements. They convert a larger percentage of electricity into visible light, making them ideal for commercial and industrial applications where energy costs are a concern.

SMD LEDs also offer excellent efficiency but may require more complex circuits for multi-chip arrangements, especially in RGB or color-changing designs. While slightly less dense than COB modules, SMDs remain an energy-conscious choice for flexible lighting layouts.

Standard LEDs lag behind in efficiency due to older technology, higher heat losses, and lower lumen output per watt.

Thermal Management – Handling Heat for Longevity

Heat management is a critical factor for LED performance and lifespan. COB LEDs generate concentrated heat because of the high density of chips in a small area. Effective thermal management — including heat sinks, aluminum substrates, and advanced board design — is essential to prevent overheating and maintain brightness over time. Without proper heat dissipation, COB LEDs may suffer reduced efficiency and shorter operational life.

SMD LEDs, by spreading chips across a larger area, dissipate heat more evenly. This design often allows for cooler operation, reducing the risk of thermal degradation. They may be better suited for installations where space for heat sinks is limited or where long-term reliability is a priority.

Standard LEDs produce less heat overall, but their lower brightness and efficiency make them less relevant in demanding lighting applications.

Reliability – Lifespan and Consistency

Reliability is closely linked to thermal performance, electrical stability, and build quality. COB LEDs can achieve long lifespans of 50,000 hours or more if properly designed and cooled. Their integrated structure reduces component failure points but makes them less modular — a failure in one part may require replacing the entire module.

SMD LEDs are highly reliable and modular. If a single diode fails, it does not necessarily compromise the entire fixture. This modularity simplifies maintenance, especially in large-scale installations like LED strips or commercial panels.

Standard LEDs are durable for basic applications, but their lower efficiency and brightness, combined with older technology, make them less suitable for long-term or high-performance projects.

Putting Performance Metrics Into Perspective

When comparing LED COB vs SMD and standard LEDs, these performance metrics highlight clear trade-offs:

- COB LEDs: Superior brightness and lumen density, excellent energy efficiency, require careful thermal management, high-quality reliability.

- SMD LEDs: Flexible design, good efficiency, distributed heat management, modular and easy to maintain.

- Standard LEDs: Basic functionality, low brightness and efficiency, minimal heat issues, simpler reliability.

Understanding these metrics is crucial for matching LED technology to your application, whether it’s a high-intensity spotlight, a flexible decorative panel, or a long-lasting general illumination fixture.

Advantages & Disadvantages: COB vs SMD

When deciding between LED COB LED and SMD or LED, it’s important to weigh both the advantages and disadvantages of each technology. Every LED type has unique strengths and trade-offs, and understanding these will help you choose the most suitable option for your lighting application.

Advantages of COB LEDs

COB LEDs have become a popular choice in high-performance lighting for several reasons:

- High Brightness and Lumen Density – COB LEDs pack multiple chips closely together, delivering intense light output in a small footprint. This makes them ideal for downlights, spotlights, and high-bay lighting.

- Uniform Light Distribution – Because the chips form a single light-emitting surface, COB LEDs produce smooth, continuous illumination without the “dot” effect common in SMD or LED strips.

- Simpler Circuit Design – COB modules usually require a single driver, reducing complexity compared to multi-chip SMD assemblies.

- Energy Efficiency – The dense chip arrangement and integrated design allow COB LEDs to convert more electrical energy into visible light, making them cost-effective for long-term use.

- Compact and Integrated Form – COB LEDs can achieve high output in small fixtures, which is advantageous for architectural and industrial applications where space is limited.

Disadvantages of COB LEDs

Despite their benefits, COB LEDs do have some limitations:

- Thermal Challenges – High chip density generates significant heat, requiring effective heat sinks and thermal management systems to prevent overheating and performance degradation.

- Limited Design Flexibility – The integrated chip arrangement makes COB LEDs less adaptable for color mixing or customized layouts compared to SMD LEDs.

- Maintenance Concerns – If one part of the COB module fails, the entire unit often needs replacement, unlike SMD LEDs, which allow individual diode replacement.

- Higher Initial Cost – COB LEDs are generally more expensive upfront than SMD modules due to their advanced assembly and materials.

Advantages of SMD LEDs

SMD LEDs offer a different set of benefits, making them highly versatile:

- Flexible Design Options – SMD LEDs can be arranged in various configurations, enabling RGB color mixing, dynamic lighting effects, and custom layouts.

- Distributed Heat – Because chips are spaced out, SMD LEDs run cooler and reduce thermal stress, which can enhance longevity.

- Modular Maintenance – Individual diodes can often be replaced without affecting the entire system, making SMD solutions easier to maintain.

- Broad Application Range – Ideal for LED strips, panels, decorative fixtures, and displays due to their adaptable form factor.

- Lower Initial Cost – SMD LEDs are widely manufactured and generally more affordable upfront compared to COB modules.

Disadvantages of SMD LEDs

However, SMD LEDs also have some drawbacks:

- Light Uniformity – Individual chips may create a “dotted” light pattern if not diffused, which can be less desirable in applications requiring smooth, continuous illumination.

- Lower Lumen Density – Compared to COB LEDs, SMD modules may require more units to achieve equivalent brightness in a compact area.

- Complex Circuitry for Multi-Chip Systems – For RGB or high-density configurations, the wiring and driver setup can be more complicated.

- Potential Hotspots – While heat is more spread out, improperly designed SMD arrays can still create localized hotspots that affect performance.

Choosing Between COB and SMD

The choice between COB LED and SMD LED depends on your priorities:

- Select COB LED if your goal is high-intensity, uniform illumination in a compact fixture, such as downlights, industrial lighting, or spotlights.

- Choose SMD LED when flexibility, color control, and modular design are more important, such as in LED strips, panels, displays, and decorative lighting.

Use Cases & Applications

Understanding the COB LED definition and how it compares to SMD or LED types is only part of the equation. The next step is to explore their real-world applications. Different LED technologies excel in specific scenarios, and choosing the right type depends on brightness requirements, light uniformity, thermal management, and design flexibility. Let’s break down where LED COB LED and SMD LEDs shine.

COB LED Applications

COB LEDs are known for their high-intensity, uniform light, making them suitable for situations where a powerful and consistent beam is required:

- Commercial & Industrial Lighting – Warehouses, factories, and large retail spaces benefit from COB LEDs because their high lumen density illuminates large areas efficiently.

- Downlights & Spotlights – In homes, offices, and galleries, COB LEDs provide smooth, glare-free lighting for task areas, highlighting artwork or architectural features.

- High-Bay Lighting – Sports arenas, exhibition halls, and gymnasiums require high-output lighting, making COB LEDs ideal for overhead applications.

- Outdoor & Floodlighting – The concentrated light of COB modules works well for security lighting, streetlights, and parking lots, where long-range visibility is essential.

- Stage & Studio Lighting – Uniform color and intensity make COB LEDs a preferred choice for professional lighting setups, including photography, video production, and theaters.

Because COB LEDs focus on uniformity and brightness, they are less commonly used for decorative or color-changing applications.

SMD LED Applications

SMD LEDs excel in versatility and adaptability, especially in applications where modularity, color control, or surface coverage is important:

- LED Strips & Accent Lighting – SMD LEDs are widely used in under-cabinet lighting, cove lighting, and furniture accents due to their flexible form factor.

- Display Panels & Screens – High-density SMD arrays enable full-color displays, digital signage, and video walls.

- RGB & Decorative Lighting – Multi-chip SMDs allow for dynamic color effects and mood lighting in homes, restaurants, and entertainment venues.

- Architectural Lighting – SMD modules can be shaped to highlight building facades, pathways, or landscape features with precise control.

- Automotive & Electronics Applications – Dashboards, backlighting, and indicator systems often use SMD LEDs because of their small size and easy integration.

SMD LEDs are ideal when flexibility and design adaptability matter more than maximum intensity or lumen density.

Standard LED Applications

Though largely replaced in modern general lighting, standard LEDs (e.g., DIP LEDs) still have niche applications:

- Indicator Lights – Panel indicators, switches, and control boards benefit from simple, reliable LEDs.

- Signage – Outdoor and indoor signs that require individual point lighting.

- Low-Power Decorative Use – Basic light strings, toys, and small appliances.

While standard LEDs are less versatile than COB or SMD LEDs, they remain cost-effective and reliable for low-intensity lighting needs.

Matching LED Technology to Your Needs

When considering LED COB vs SMD for a project, the choice should align with:

- Brightness Requirements – Choose COB for high-intensity illumination; SMD for medium-intensity, broader coverage.

- Light Uniformity – COB delivers smooth, glare-free light, ideal for task or architectural lighting.

- Design Flexibility – SMD excels in modular, customizable setups, including RGB and decorative lighting.

- Thermal Management & Maintenance – COB requires careful heat control; SMD is easier to maintain and replace.

By understanding these applications, you can ensure that your choice of LED COB LED, SMD, or standard LED matches the specific demands of the space, whether it’s residential, commercial, industrial, or decorative.

Conclusion & Recommendations

We’ve journeyed through the world of led cob led, contrasting it with more familiar packaging like SMD. The key takeaways:

- LED is a broad term; COB is a specific packaging/assembly method.

- led vs cob led is thus a framing — COB is part of the LED family with distinct traits.

- led cob vs smd trade off uniformity vs flexibility, density vs layout adaptability.

- Thermal design, driver choice, optical treatment, and cost modeling are essential to success.

- Neither COB nor SMD is universally “better” — your project constraints, goals, and environment dictate the winner.

Recommendations (by scenario):

- Want clean, high-intensity, compact light? Go led cob led.

- Need RGB, custom shapes, or highly flexible designs? Lean smd or led.

- In critical lighting (studio, architectural), do prototypes, thermals, long-term tests.

- Use quality materials and partner with reputable module suppliers.

Frequently Asked Questions

What is the difference between LED and COB LED?

The main difference lies in the structure and light output. Standard LEDs consist of individual diodes, while COB LEDs integrate multiple chips onto a single substrate, creating a uniform, high-intensity light source. COB LEDs deliver smoother illumination and higher lumen density, whereas standard LEDs are modular, flexible, and often used for smaller or decorative applications.

What is a COB type LED?

A COB type LED is a “Chip on Board” module where multiple LED chips are mounted closely together on a single board. This design produces a compact, powerful, and uniform light source, ideal for applications like downlights, spotlights, high-bay fixtures, and architectural lighting.

What are the three types of LEDs?

The three most common types of LEDs are:

1. Standard LEDs – Single diodes, typically used for indicators and signage.

2. SMD LEDs (Surface-Mounted Device) – Individual diodes mounted on a PCB for flexible layouts and RGB applications.

3. COB LEDs (Chip on Board) – Multiple chips integrated on a single substrate for high-intensity, uniform light.Which is better LED or SMD?

It depends on your application. SMD LEDs are better for flexible layouts, color mixing, and broad light coverage, while standard LEDs are simpler, cost-effective, and suitable for indicator lights or low-intensity purposes. SMD offers more design versatility than traditional LEDs.

What are the disadvantages of SMD LED?

SMD LEDs may create a “dotted” light effect if not diffused properly, have lower lumen density compared to COB LEDs, and can require more complex circuitry for multi-chip or RGB configurations. They also generate localized heat if poorly designed.

Which is better, SMD or COB LED?

COB LEDs are better for high-intensity, uniform lighting where smooth illumination is critical. SMD LEDs are superior for flexible designs, color effects, and modular applications. Your choice should depend on brightness needs, thermal management, and layout requirements.

What’s a COB LED?

COB LED stands for Chip on Board LED, where multiple LED chips are mounted onto a single substrate. This configuration allows for high lumen density, compact size, and uniform light output, making it ideal for commercial, industrial, and architectural lighting.

How do COB LEDs manage heat?

COB LEDs generate concentrated heat due to their high chip density. Effective thermal management involves using heat sinks, aluminum or ceramic substrates, and proper fixture design to dissipate heat efficiently, maintaining performance and longevity.

Can SMD LEDs replace COB LEDs?

In some applications, yes. SMD LEDs can be arranged in high-density arrays to approximate the brightness and coverage of COB LEDs. However, they may lack the uniformity and high lumen density of a true COB module, making them less ideal for focused or high-intensity applications.

Where should COB LEDs be used instead of SMD LEDs?

COB LEDs are ideal for applications requiring uniform, high-intensity light, such as:

• Downlights and spotlights

• High-bay industrial lighting

• Outdoor floodlights and security lighting

• Architectural accent lighting

SMD LEDs, meanwhile, excel in flexible layouts, RGB applications, and decorative lighting where modularity is important.